Packaging

At Stumaco you can also find a wide range of machines to wrap up your products. The packaging line includes several machines to process your products quickly and efficiently.

A complete line to wrap your products.

Your own company’s packaging line can give you a bunch of advantages. You can manufacture, check and wrap your product yourself. With Stumaco’s packing units your products will be taken out of the box or octabin and put near to the weighing unit. That way your weighing unit will have the possibility to reach to maximum amount of strokes.

How does a packaging line work?

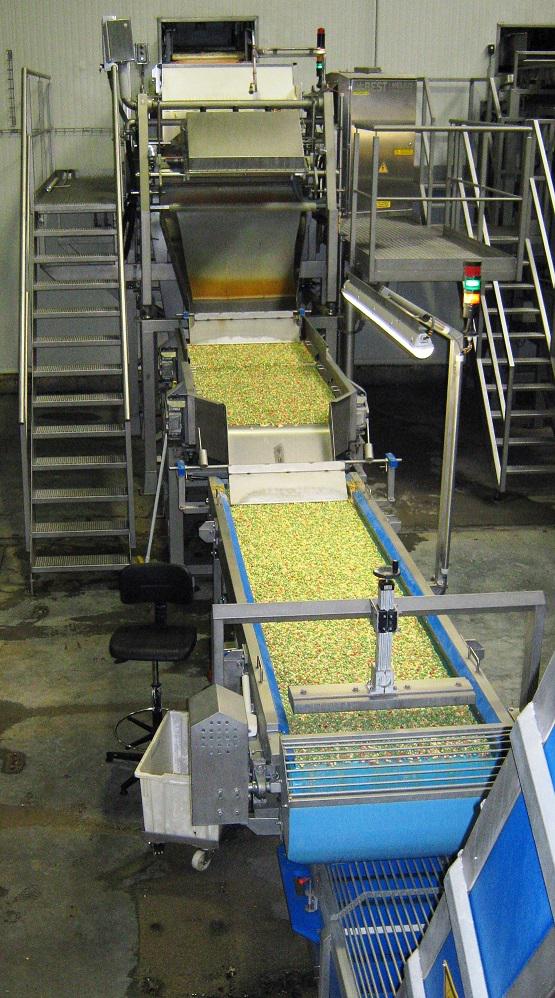

First the goods are poured out of the boxes or octabins into a storage hopper. Then an extractor system takes the product out of the storage hopper and the bigger pieces will be broken. Everything will be sorted and scanned to find foreign objects, shapes or metal. Potentially the products will get glazed. The product lies on the inspection belt and because of the elevator system it gets offered to the weighing unit. After weighing the product gets wrapped up in the packaging machine. Which you can find under the weighing unit. Ultimately, the packaged items will be carried off through a metal detector for a final checkup.

Stumaco’s packaging lines have a couple of typical components:

- drill unit

- roller conveyor

- box tipper

- feed hopper

- discharge belt, -screw and –shaker,

- roll crusher

- grading vibrators

- scanner

- glazing installation

- inspection conveyor

- elevator type redler

- storing- and dosing vibratory conveyor

- metal detector

- weighing head with underlying packaging machine

Any questions about the components of a good packaging line? Contact us